-

Projects

Energy harvesting from Biogas and renewable Hydrogen intensified through tri-functional solids and Unconventional reactor Configurations (EBHUC)

- Start date: 01-06-2023

- End date: 31-05-2026

- Coordinator: José Ángel Peña

- Type: National (AEI)

Biogas is a scarcely exploited resource in Spain. Currently, there are hardly any infrastructures for its utilization, contrasting with the situation in Northern Europe. The document “Hoja de ruta del biogás en España” (Biogas Roadmap in Spain), presented in October 2020 by the Spanish Government, foresees a production capacity of ca. 34 TWh/year by harnessing this renewable resource. Among its uses is heat production and its transformation through reforming (dry or with steam) into hydrogen. Among the primary sources of biogas, it can be highlighted the organic fraction of solid waste (OFMSW) or the sludge from wastewater treatment plants (WWTP). The capacity of other industries such as agricultural, cattle or agri-food should not be forgotten.

Our research group (CREG, https://creg.i3a.es) has been working for years on the thermocatalytic methanation of CO2 contained in biogas. In this way, Synthetic Natural Gas (SNG) with characteristics analogous to fossil fuels can be obtained, which can be consumed on-site or injected in the yet existing natural gas network. In both cases, this transformation (“upgrading”) is particularly interesting as a means of transportation (via pipeline) and storage of renewable energy.

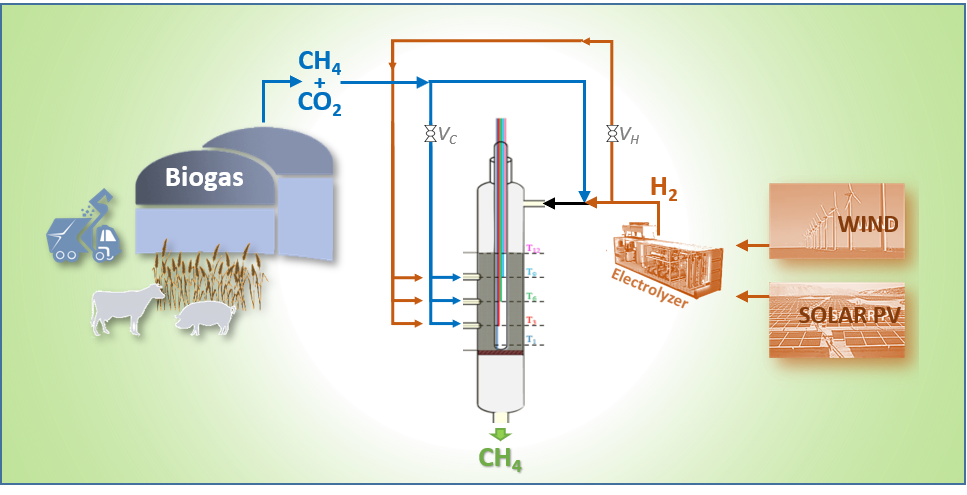

This research project consists in studying the use of CO2-rich gas streams, jointly with renewable hydrogen to produce synthetic natural gas (SNG or biomethane). As a source of CO2, a biogas with a composition close to that from municipal solid wastes landfills (MSW) has been chosen. As a source of hydrogen, high purity H2 will be used, such as that produced from surplus electricity (from wind or photovoltaic installations in “off-peak” hours -lower demand than supply-) by electrolysis. The resulting product is the well-known “Synthetic Natural Gas” (or “Renewable Natural Gas” or “Biomethane”) with characteristics comparable to those of fossil origin, but with a completely “green” origin. Such product could be injected into the already existing natural gas network favouring energy storage and transport.

To carry out this process, it has been proposed to adopt two ways operating in parallel: one A) using conventional reactors (fixed bed -FBR- and fluidized bed -FLBR-) and multifunctional solids (tri-functional) operating cyclically in 2 stages; and another B) more traditional, but with “unconventional” reactor configurations such us polytropic (multiple feed -PFBR-) and a membrane wall fixed bed reactor (MB-FBR).

More información:

- A. Sanz-Martínez, P. Durán, V.D. Mercader, E. Francés, J.Á. Peña, J. Herguido, Biogas Upgrading by CO2 Methanation with Ni-, Ni-Fe-, and Ru-Based Catalysts, Catalysts 12 (2022). https://doi.org/10.3390/catal12121609.

- P. Aragüés-Aldea, A. Sanz-Martínez, P. Durán, E. Francés, J.A. Peña, J. Herguido, Improving CO2 methanation performance by distributed feeding in a Ni-Mn catalyst fixed bed reactor, Fuel 321 (2022) 124075. https://doi.org/10.1016/J.FUEL.2022.124075.

Project: PID2022-136947OB-I00