- Start date: 2014

- End date: 2017

- Coordinator: Javier Herguido

- Type: National (DGI)

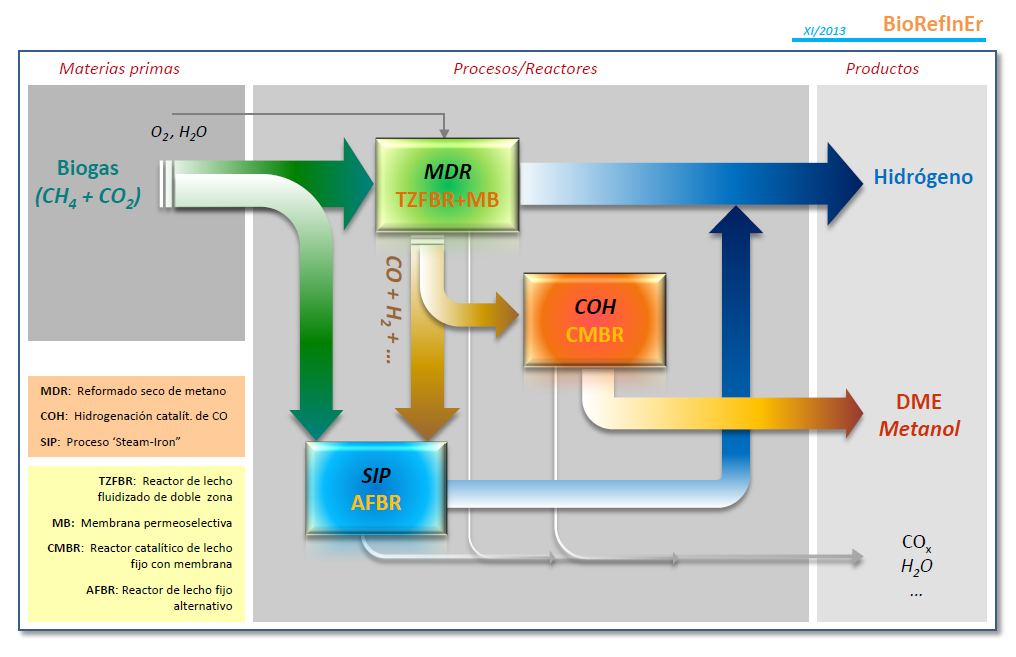

This research project proposes the use of a non-fossil, renewable nature energy source as is biogas. It encompasses the challenge of a sustainable energy supply, respectful towards the environment, and that contributes to the control of wastes coming from various sources such as municipal solid wastes, agricultural and livestock and those derived from industry like sewage sludge. To accomplish that goal, production of hydrogen as energy vector has been chosen as primary target, as well as other alternative fuels like methanol (MetOH) and dimethyleter (DME) which take advantage of the hydrogen and carbon monoxide that emerge as intermediary compounds.

The methodology consists of combining several technologies within the same process. This includes on the one side the complex reaction network that gathers: (a) methane dry reforming (MDR), (b) syngas catalytic hydrogenation (COH) and (c) regeneration of catalysts by combustion of the carbonaceous residue generated in the above mentioned reactions. On the other side it deals with the unavoidable separation processes: (d) separation of hydrogen mediated by metallic oxides subjected to reduction-oxidation cycles (“steam-iron process” or -SIP-), (e) separation of hydrogen by permselective membranes, and (f) selective separations by membranes based on zeolites. The combination of these processes of reaction + separation + regeneration implies a notorious intensification of the whole process, what confers it a remarkable character of sustainability, integrating different basic operations in a short number of operating units.

The method implies also the use of singular reactors like the “Two Zone Fluidized Bed Reactor” (TZFBR) in which besides a simultaneous reaction and regeneration, it is pretended to perform the simultaneous removal of pure hydrogen by inclusion of a permselective membrane (MB), and the catalytic membrane reactor (CMBR), as long as other conventional reactors like fixed bed ones, but with the singularity of operating in an alternate schedule (AFBR) of reduction-oxidation depending of the reductive features of the feed.

Along the project it is expected the determination of the optimal conditions for the whole set of units by the experimental analysis of each one of the three main blocks that configure the process:

(i) MDR in TZFBR+MB

(ii) COH in CMBR

(iii) SIP in AFBR

For such purpose an accurate study will be carried out on the different configurations of reactors, materials (permselective membranes, catalysts, metallic oxides,…) and operation parameters (flows, temperatures, partial pressures, permeation pressures,…).

The main objective of the study is achieving the maximum yield of the desired products (Hydrogen, MetOH, DME) in a stable and selective way. All of this keeping in mind that implicitly the number of basic units and their dimensions are being restricted for each one of the blocks (intensification), as well as the impurity content (specially CO) in the hydrogen stream, should be low enough to be fed to a PEMFC for its final exploitation.

Project: ENE2013-44350-R