- Start date: 2000

- End date: 2001

- Coordinator: Javier Herguido

- Type: Regional (DGA)

The general objective of the project was to obtain an effective and low-cost catalytic reactor for the combustion of hydrocarbons, such as methane in lean mixtures, in order to use them energetically and prevent their emission into the atmosphere.

To achieve this goal, several milestones were marked:

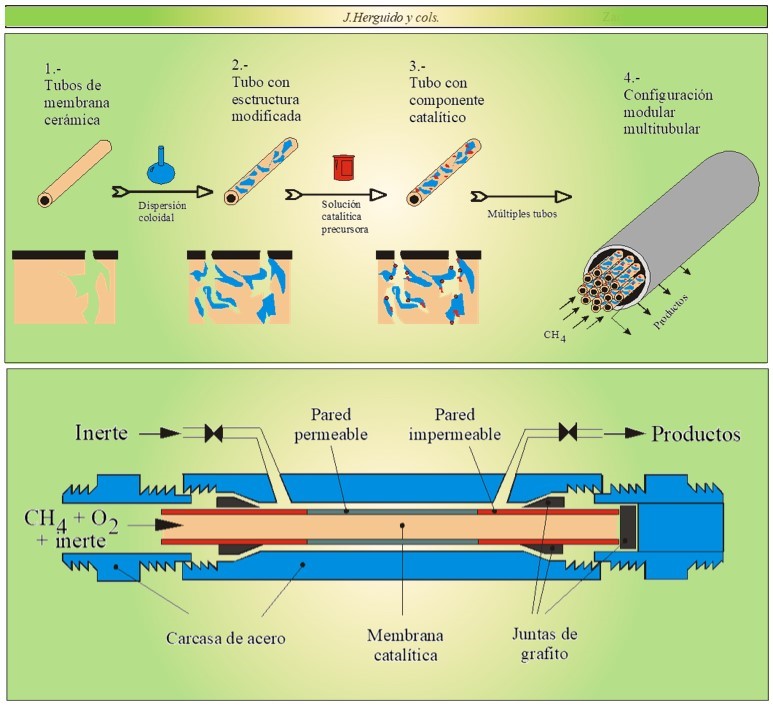

1.- Obtaining suitable catalysts. The objective was to prepare cheap and stable metal oxides with sufficient catalytic activity for the combustion. Selected mixtures of metal oxides, such as perovskites and metal oxides (Fe, Co, …), were studied as opposed to traditional catalysts for methane combustion (supported noble metals, such as Pd/Al2O3 and Pt/Al2O3, or their combination with Rh or Ir).

2.- Obtaining catalytic membranes using the selected catalysts. This objective led to the development of a viable method for deposition of the catalysts on the ceramic membrane, including the adaptation of this commercial membrane to the needs of the reaction, especially with regard its permeability.

3.- Obtaining an optimal combustor. The most suitable catalysts were used in a catalytic membrane reactor. The basis of this type of contactor consists of carrying out catalytic combustion by passing the gases through a mesoporous ceramic membrane in which the catalyst had previously been deposited. In this way, better contact between the hydrocarbon and the catalyst was achieved, so increasing the combustion efficiency.

Project: P093/99-T