The group is researching new technologies for hydrogen production and use. In particular, the steam-iron process (SIP) for hydrogen production and purification has been studied. This process, related to Chemical Looping, can be used to produce and purify H2 from a stream resulting from the pyrolysis of natural gas, synthesis gas, biogas (previously desulphurised) or bio-oil fractions. The SIP process is based on a cyclic sequence of reduction and oxidation (REDOX) stages of a metal-based material (usually iron with additives). The REDOX material may be accompanied by a catalyst to promote H2 production. In this way, the intensification of the process is achieved by carrying out hydrogen production and purification in the same process unit.

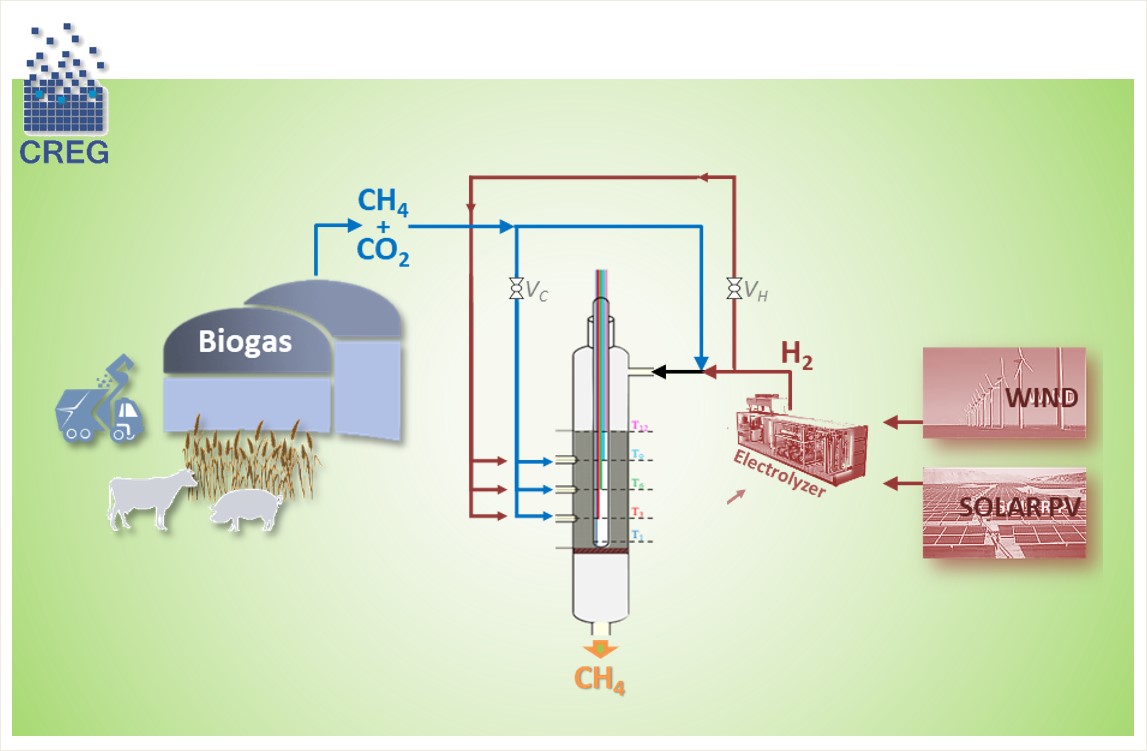

Regarding hydrogen energy applications, non-conventional reactor configurations (polytropic, fluidised, membrane, etc.) are being studied, together with new catalysts, to carry out the methanation of carbon dioxide. The process constitutes a significant part of the concept known as “Power to Gas” (PtG or P2G), in which surplus renewable electrical energy is invested to produce electrolytic H2, which together with CO2 from renewable sources (Chemical Looping Combustion), gasification or oxy-combustion of biomass or biogas, is transformed into methane, giving rise to a synthetic natural gas (SNG). This can be injected into the existing natural gas grid, facilitating the transport and storage of energy.