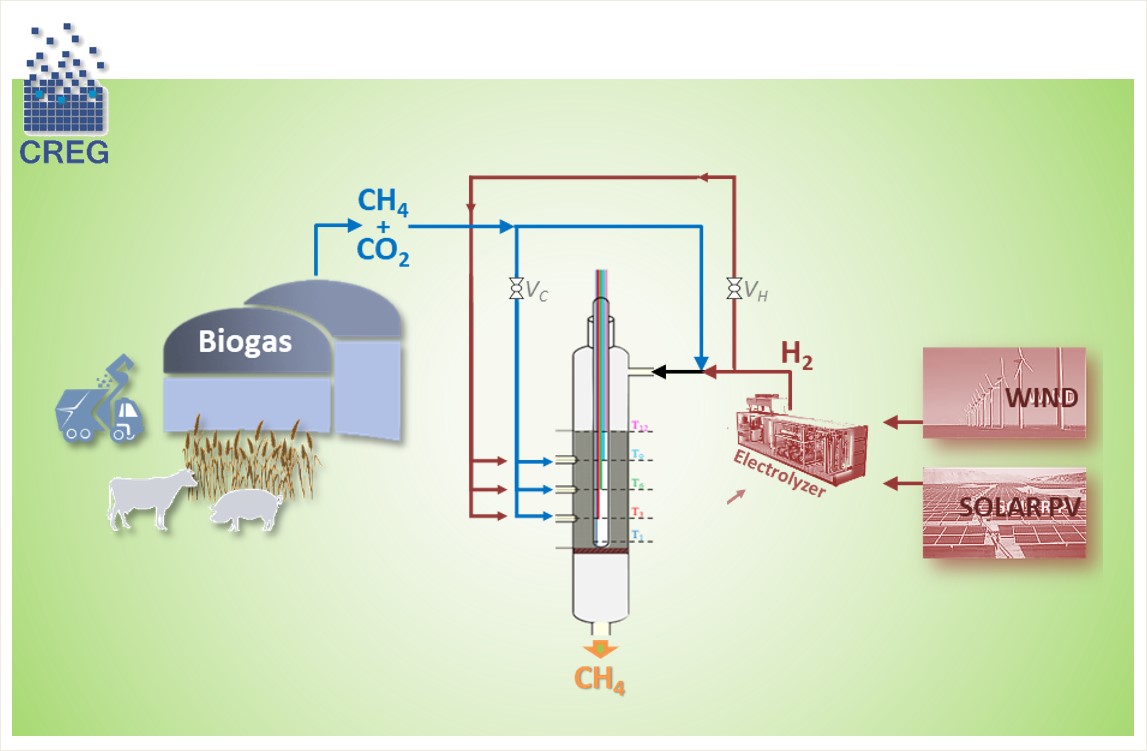

Hydrogen technologies

The group is researching new technologies for hydrogen production and use. In particular, the steam-iron process (SIP) for hydrogen production and purification has been studied. This process, related to Chemical Looping, can be used to produce and purify H2 from a stream resulting from the pyrolysis of natural gas, synthesis gas, biogas (previously desulphurised) or bio-oil fractions. The SIP process is based on a cyclic sequence of reduction and oxidation (REDOX) stages of a metal-based material (usually iron with additives). The REDOX material may be accompanied by a catalyst to promote H2 production. In this way, the intensification of the process is achieved by carrying out hydrogen production and purification in the same process unit.

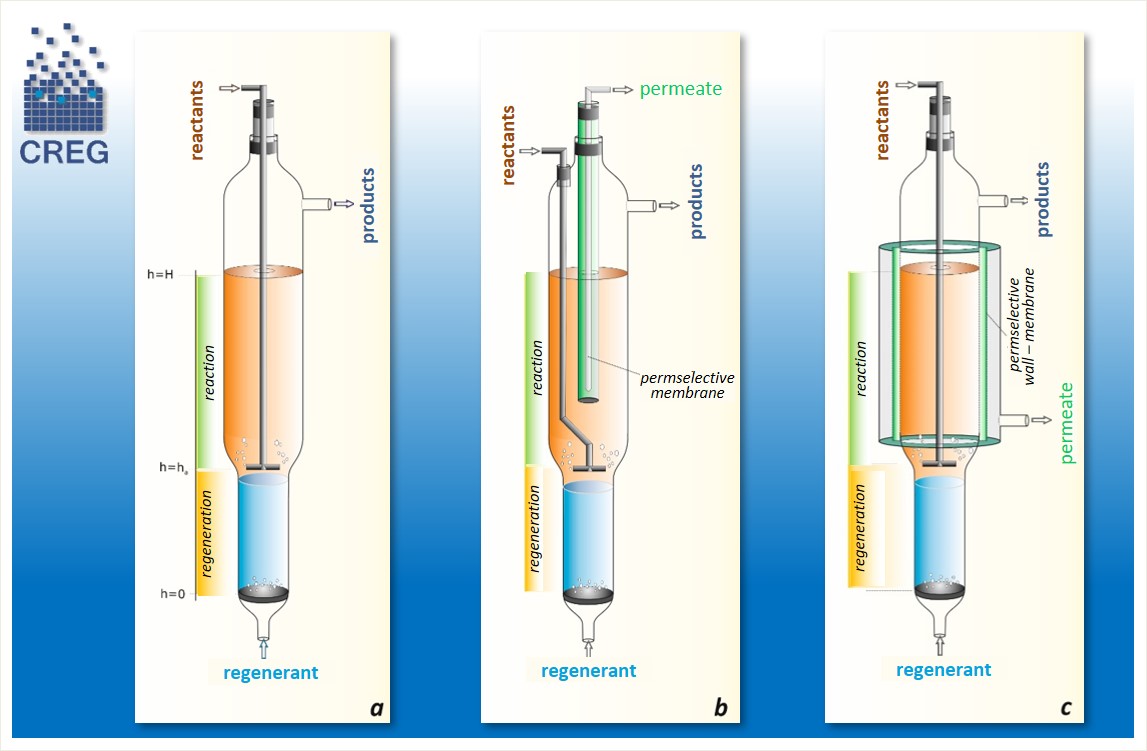

Reactor Engineering

Innovative chemical reactors are being developed for various processes, seeking more effective systems, within the trend towards intensification of processes to achieve more compact, safer equipment with less environmental impact. Work has been carried out on two types of innovative reactors: membrane reactors and two-zone fluidised bed reactors.

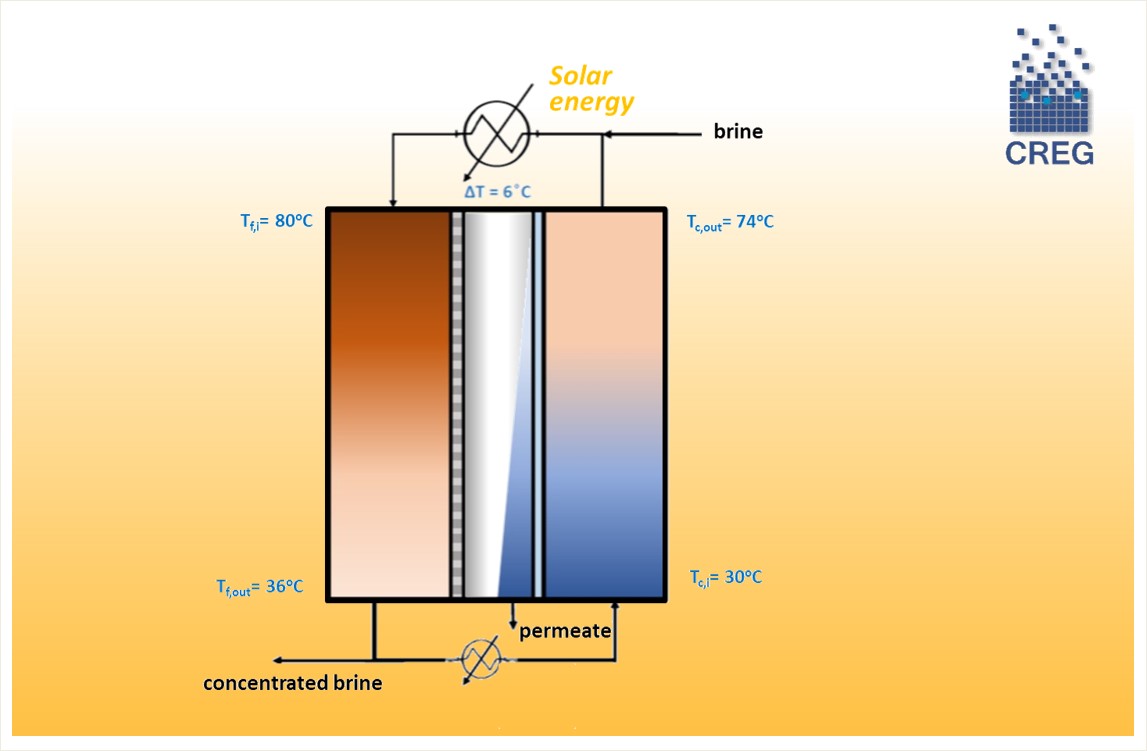

Membrane distillation

In collaboration with a Spanish company, the use of membrane distillation technology to concentrate a stream is being studied. This technique uses the heat of waste streams or solar energy to remove water from concentrated solutions. It is particularly suitable when reverse osmosis cannot be applied because of the high concentration of water in the solution.